-

Bulloneria Bellicini

quality since 1978 -

Bulloneria Bellicini

quality since 1978

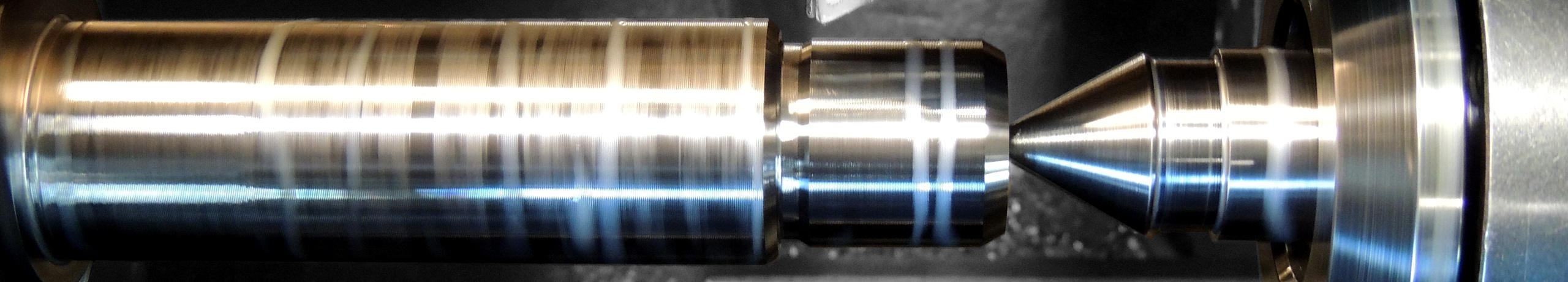

Bulloneria Bellicini has long undertaken a process aimed at achieving a high quality product, through continuous technological improvement, selection of suppliers, selection and ongoing training of operators, management of a production system aimed at a continuous control of its product manufacturing process.

Bulloneria Bellicini has long undertaken a process aimed at achieving a high quality product, through continuous technological improvement, selection of suppliers, selection and ongoing training of operators, management of a production system aimed at a continuous control of its product manufacturing process.

This objective has involved acquiring and maintaining the ISO 9001 quality certificate since 2006.

2024 CertificateDownload PDF

Quality PolicyDownload PDF

- 1.Product quality control:

- A.Strict criteria for selecting the raw material suppliers: verification of supplier's ability to meet the material supply requirements (ISO 898)

- B.Internal checks of the steel bars during acceptance;

- C.Monitoring and recording of all production stages;

- D.Problem prevention and timely resolution;

- E.Testing at independent and external certified laboratories carried out periodically on the product, as well as on request for specific customer needs: e.g. hardness tests (Rockwell, Brinell, Vickers), tensile testing, quantometric analysis, decarburisation check, video recorder.

- F.Traceability of the product supplied and the work phases it has undergone over time: a job order management system, allowing customers to receive documentation on the processing steps relating to the individual production batches, whose numbering characterises and identifies each packaging label.

The documentation includes:- inspections and dimensional measurements carried out during the production process;

- the certificate of the steel used with its chemical component analysis;

- the certification of the heat treatment or coating performed;

- any tests related to the mechanical properties of the piece.

- 2. Company management quality control

- A.Definition of the objectives for improvement

- B.Verification of the effectiveness of introduced actions and measure

- C.Improvement of human resources, through updates and specific training courses for the use of machinery